Tooling

Our tooling activities cover the complete lifecycle of injection moulds, including design, manufacturing, modification, repair and maintenance. Annual production volume exceeds 2,500 moulds. Our key competetive advantage lies in flexibility and fast response times, enabled by the close integration of injection moulding and tool manufacturing as in-house resources.

Production of injection moulding tools

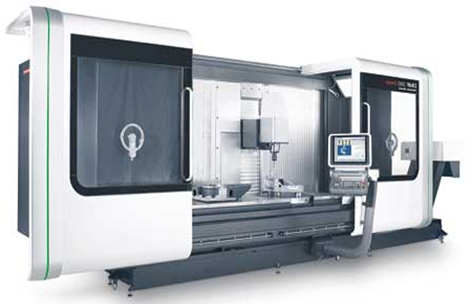

Our company operates a fully equipped tooling facility in Kaposvár, utilizing modern CNC milling, EDM die-sinking, and precision machining technologies to manufacture injection moulds for serial automotive production.

Modification and repair of injection moulding tools

We support injection mould manufacturing, modifications and repairs with structured part validation and quality checks, ensuring that tooling changes result in stable processes and customer-approved part quality.

CNC custom and series production

We manufacture custom-made and small-series precision parts based on 2D and 3D technical documentation, supporting both tooling projects and customer-specific manufacturing needs.

Laser welding

Using stationary and mobile laser welding systems, we perform high-precision repairs and modifications on injection moulds and tooling components, independent of tool size or complexity.

Tool design

Our in-house tooling engineering team supports projects from concept to approval, including DFM analysis, runner layout, wall thickness optimization, shrinkage analysis and tolerance definition. Tool concepts and designs are validated through 3D and 2D documentation and reviewed together with the customer prior to manufacturing.

Metrology lab services

Our metrology laboratory is equipped with Hexagon coordinate measuring machines (CMM), optical measurement systems, 3D scanners, and handheld measuring instruments. Material testing capabilites include Melt Flow Index (MFI) and raw material moisture measurement.